The Future of 3D Printing

The Future of 3D Printing

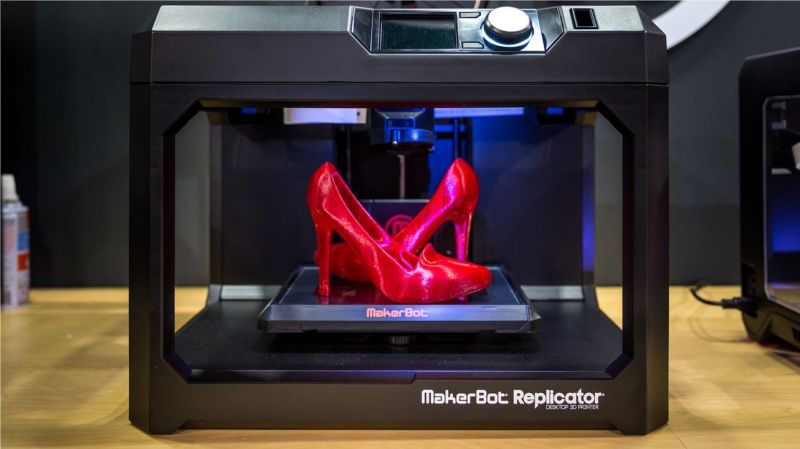

3D printing has only become quite popular recently. It became popular when people discovered how simple its application is. Early on, 3D printing had a steep learning curve, and most models were very expensive. However, today these printers are now very accessible and affordable. These printers are beneficial in every sector, from manufacturing to education.

What Is 3D Printing?

3D printers produce images in the form of a three-dimensional solid object. The focus of a 3D printer is to lay materials down one on top of the other until the object is formed. Every one of these layers is a thin slice of the overall object. For complex shapes, 3D printing uses less material than traditional manufacturing methods.

3D printing in the workplace has numerous industrial applications. It is used today in a number of industries and has transformed the manufacturing industry.

How Is 3D Impacting Various Industries?

- Dental and medical

From bioprinting to prosthetics and medical devices, 3D printing is widely used in the medical and dental industries. CT scanning, for example, provides a variety of patient-specific solutions, such as dental appliances and implants, as well as enhanced medical devices and personalized healthcare.

- Automotive

Several automotive industries, including performance racing and motorsports, are now using 3D printers. 3D printers are used by automotive manufacturers to produce a variety of parts. 3D printing can be used to create complex geometric shapes like inner slits or fine mesh, as well as thin walls.

- Defence and Aerospace

3D printing has had a positive impact on the aerospace and defence industry. It is used in the process of manufacturing functional parts such as air ducts, wall panels, and structural metal components for aircraft.

- Drone

Customized drones can be built using 3D printing, with the exception of electronic components, which cannot be 3D printed. With the help of 3D printing, it is possible to produce a variety of accessories for the proper storage of a drone. Using the additive manufacturing process, drones of various sizes and weights can be produced at lower costs.

What is the cost of a machine, and what will it get you?

First, you should know that there are three main types of 3D printing, and their costs are different. The Fused Deposition Modelling is the most affordable, while the Selective Laser Sintering and Stereo-lithography cost more. The printers come at a starting price of $500 dollars, while the Selective Laser Sintering is the most expensive. The type you get will depend on your application. The 3D printers have their uses.

The 3D printers have low maintenance costs, especially the Fused Deposition Modelling printers. However, no matter how much you spend on your 3D printer, the machine tends to pay for itself. Considering that many industries have use for it, you will certainly get returns for your investment.